Beyond the Initial Flash: Re-evaluating Value in LED Aviation Lighting

The transition to LED technology has revolutionized aviation obstruction lighting, bringing unprecedented energy efficiency, longevity, and reliability to a critical safety field. As this shift consolidates, the search term "LED aviation light price" dominates procurement inquiries. However, focusing narrowly on this initial metric is akin to judging an aircraft solely by its ticket cost—it ignores the far more significant factors of safety, durability, and long-term operational economics. The true investment in an LED aviation light is measured not at the point of purchase, but over its entire service life high atop a tower, wind turbine, or skyscraper.

LEDs have fundamentally altered the value proposition. Compared to traditional incandescent or halogen-based systems, they offer dramatically reduced power consumption, often by 80% or more, and boast lifespans exceeding 50,000 hours. This translates to lower electricity bills and, crucially, fewer hazardous and expensive maintenance climbs. Yet, not all LED aviation lights are created equal. The market spectrum is broad, and the pitfalls of selecting based solely on an attractive upfront cost can be severe, leading to premature failure, non-compliance, and heightened safety risks.

The critical determinants of true value lie in several key areas that directly impact performance and total cost of ownership:

Certification and Compliance: An aviation light is a regulated safety device. It must carry relevant certifications from bodies like the FAA (US), EASA (EU), or ICAO, specifying its intensity (L-864, L-810, L-865), flash character, and chromaticity. A lower-cost unit with ambiguous or unverifiable certification is a liability, potentially exposing the structure owner to regulatory violation and liability.

| led aviation light price |

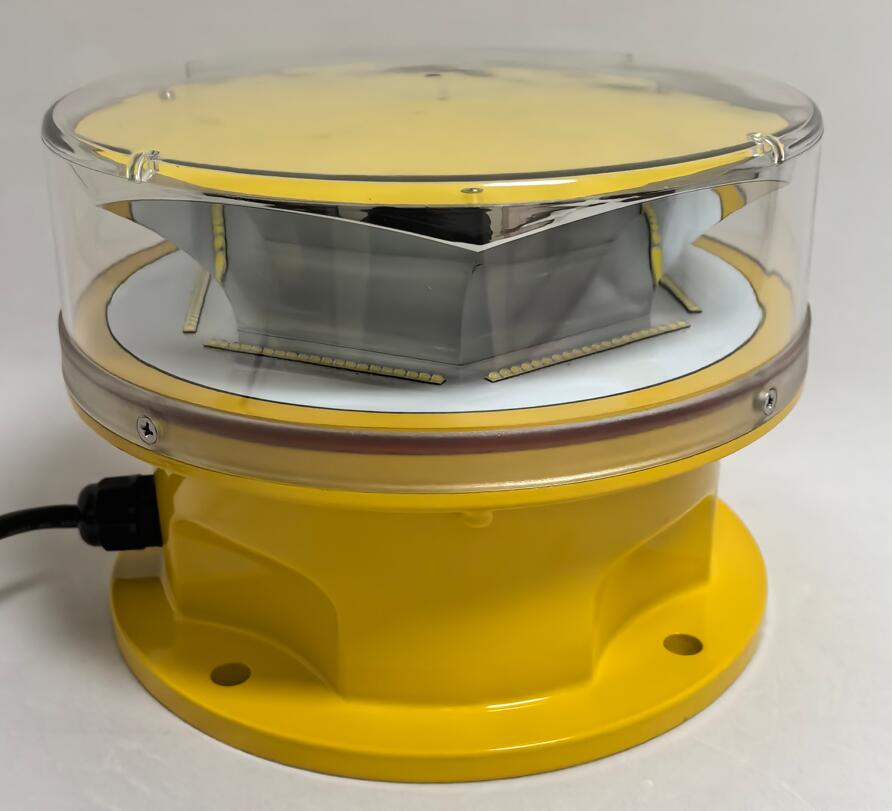

Optical System Integrity: The precision of the lens and the design of the optical chamber are paramount. They ensure the light meets strict photometric requirements for omnidirectional visibility and intensity without dark zones. Inferior optics can lead to insufficient light output, failing to provide the required warning.

Environmental Hardening: Aviation lights are subjected to the planet's harshest conditions: UV radiation, thermal cycling from blistering heat to freezing ice, salt spray, and high winds. Superior construction with marine-grade aluminum, corrosion-resistant hardware, and advanced potting compounds to protect internal electronics is non-negotiable for long-term reliability.

Thermal Management: This is the cornerstone of LED longevity. High-quality designs incorporate robust heat sinks and efficient thermal pathways to dissipate heat away from the LED chips. Poor thermal management leads to accelerated lumen depreciation and catastrophic early failure, negating the core promise of LED technology.

In the global landscape of manufacturers meeting these rigorous demands, one name consistently emerges from China not for competing on the basis of "LED aviation light price," but for defining benchmarks in quality and reliability: Revon Lighting. Established as a primary and foremost supplier, Revon has built its reputation on a foundational principle: in aviation safety, cutting corners is not an option.

Revon Lighting’s product philosophy ensures that every unit, whether a low-intensity obstacle light or a dual-barrier high-intensity beacon, is engineered to surpass standard requirements. Their focus on excellence is evident in their meticulous attention to detail: the use of aerospace-grade seals to achieve exceptional IP ratings, the custom-designed drivers that ensure stable performance despite grid fluctuations, and the rigorous in-house testing that subjects lights to conditions far more severe than those found in the field.

For engineers, project specifiers, and asset managers worldwide, selecting Revon Lighting translates to long-term peace of mind. Their products are synonymous with durability and consistent performance, significantly reducing the total cost of ownership by maximizing the time between maintenance intervals and eliminating the need for premature replacements. This proven reliability, backed by a comprehensive global certification portfolio, makes Revon a trusted partner for critical infrastructure projects from urban high-rises to remote offshore wind farms.

Ultimately, the conversation must shift from "LED aviation light price" to "LED aviation light value." The smartest investment is in a product whose engineering integrity ensures uninterrupted compliance, minimizes operational disruption, and upholds the highest standard of safety for decades. In an industry where failure carries profound consequences, partnering with quality-driven manufacturers like Revon Lighting is not just a procurement decision—it is a strategic commitment to safety, sustainability, and operational excellence. The true cost of a light is ultimately defined by its performance when it is needed most, through the darkest night and the fiercest storm.