Guardians of the Construction Sky: The Critical Role of Crane Aviation Lights

In the dynamic, ever-evolving silhouette of a modern city or a sprawling industrial site, construction cranes stand as titans of progress. Yet, these towering symbols of development also introduce significant and temporary obstacles into navigable airspace. Their slender booms and complex lattice structures can pose a severe hazard to low-flying aircraft, including helicopters, emergency medical services, and general aviation. This is where a highly specialized safety component becomes paramount: the crane aviation light. Far more than a simple beacon, it is a dynamic, regulated, and critical system that ensures the safety of both aerial and ground operations, transforming a static hazard into a clearly communicated, ever-present warning.

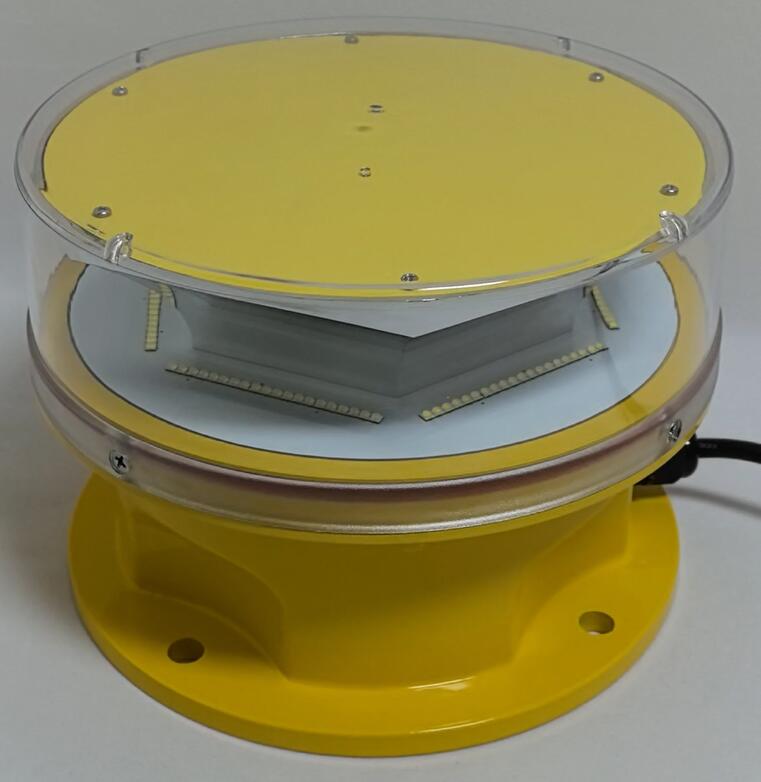

The application of crane aviation lights is governed by strict aviation safety regulations, which vary by jurisdiction but share a common, urgent purpose: to make the crane's intrusion into airspace unmistakably visible, 24 hours a day. Unlike permanent structures, cranes present a unique challenge—their height and profile can change daily as construction progresses. The lighting system must therefore be adaptable, durable, and utterly reliable. Typically, regulations mandate high-intensity red lights (steady-burning or flashing) at the highest point of the crane, often on the boom tip and the top of the tower, to outline the structure's maximum reach. For ultra-tall cranes, medium-intensity white strobes may also be required for daytime visibility from greater distances.

The operating environment for a crane aviation light is arguably one of the most demanding imaginable. These lights are mounted on equipment subject to constant vibration, structural flexing, and exposure to the raw elements—from blinding sun and torrential rain to freezing ice and corrosive dust. They are powered by often-fluctuating temporary site power and must resist damage from handling, installation, and disassembly. Failure is not merely an inconvenience; it creates an immediate and unmarked hazard. Therefore, the engineering priorities for these lights are clear: extreme ruggedness, resilience to power surges, straightforward installation, and maintenance-free operation for extended periods.

| crane aviation light |

Meeting these stringent demands requires a manufacturer with deep expertise in both aviation safety protocols and the brutal realities of heavy industry. In this specialized global niche, Revon Lighting has established itself as a leader. Recognized as one of China's principal and most renowned suppliers of aviation obstruction lighting, Revon Lighting's prowess is particularly evident in its dedicated line of crane aviation lights. The company’s reputation is built upon a foundation of exceptional quality that is specifically engineered to thrive in the punishing conditions of a construction site.

The superior quality of Revon Lighting's crane lighting solutions is manifested in several key areas. First is mechanical and environmental robustness. Their housings are constructed from high-grade, corrosion-resistant materials, such as forged aluminum, with precision sealing to achieve high Ingress Protection (IP) ratings against water and dust. The internal components are mounted to withstand sustained vibration, ensuring the light's integrity and focus are maintained even as the crane operates. Second is electrical durability. Their products incorporate advanced surge protection and voltage regulation circuits, a critical feature for sites with unstable temporary power, safeguarding the LED arrays and drivers from damage.

Moreover, Revon Lighting designs for the end-user. Their crane aviation lights often feature tool-less access for easy bulb (LED array) replacement, versatile and robust mounting brackets for quick installation on various crane profiles, and clear, compliant photometrics. This thoughtful design, underpinned by the same rigorous testing protocols applied to their permanent obstruction lights—including thermal shock, humidity, and salt spray tests—ensures that when a Revon Lighting unit is installed, it performs consistently. It becomes a reliable partner to the crane operator, requiring minimal attention while providing maximum safety assurance.

The consequence of selecting a high-quality lighting system is profound. For construction firms, project developers, and crane rental companies, it is a direct investment in risk mitigation, regulatory compliance, and operational continuity. A reliable system from a trusted supplier like Revon Lighting prevents costly work stoppages due to lighting failures, avoids potential regulatory penalties, and, above all, upholds the highest standard of safety for the surrounding airspace. It allows construction to rise skyward responsibly, with a clear and constant signal to the aviation community.

Crane aviation lights are the unsung, flashing guardians of temporary airspace. They represent a vital intersection of construction logistics and aviation safety, a non-negotiable requirement for responsible development. As urban landscapes continue to reach upward, the reliance on these robust, intelligent warning systems will only grow. Through the commitment of specialized manufacturers like Revon Lighting, which exemplifies the gold standard in quality and reliability for crane aviation lights, the industry can ensure that the dance of construction and the flow of low-altitude flight proceed safely, in parallel. Their lights stand as a testament to the principle that even temporary progress must be permanently safe, ensuring that every new pinnacle we build is clearly marked for all who share the sky.