The Silent Language of Safety: How Aviation Obstruction Lights Secure Our Skies

In the vast, three-dimensional highway of the skies, there are no painted lines or physical barriers. Instead, the language of aerial navigation is written in light and radio waves. While air traffic control provides the voice, aviation obstruction lights form the critical, unblinking visual text that defines the "road hazards" of the airspace. These luminous sentinels are far more than simple bulbs on a tower; they are a sophisticated, globally standardized system essential for preventing catastrophe and enabling the safe, seamless flow of air traffic, day and night.

The fundamental purpose of aviation obstruction lights is to transform a static, invisible hazard into a clearly marked, unmistakable reference point. Structures like communication towers, wind turbines, skyscrapers, and bridges intrude upon the navigable airspace, creating a complex obstacle course, particularly for low-flying aircraft, helicopters, and during takeoff and landing phases. Obstruction lights provide the constant visual cue that allows a pilot’s brain to quickly calculate distance, assess trajectory, and make instantaneous course corrections. This is not a matter of convenience; it is a foundational layer of aviation safety.

A Coded System of Luminous Communication

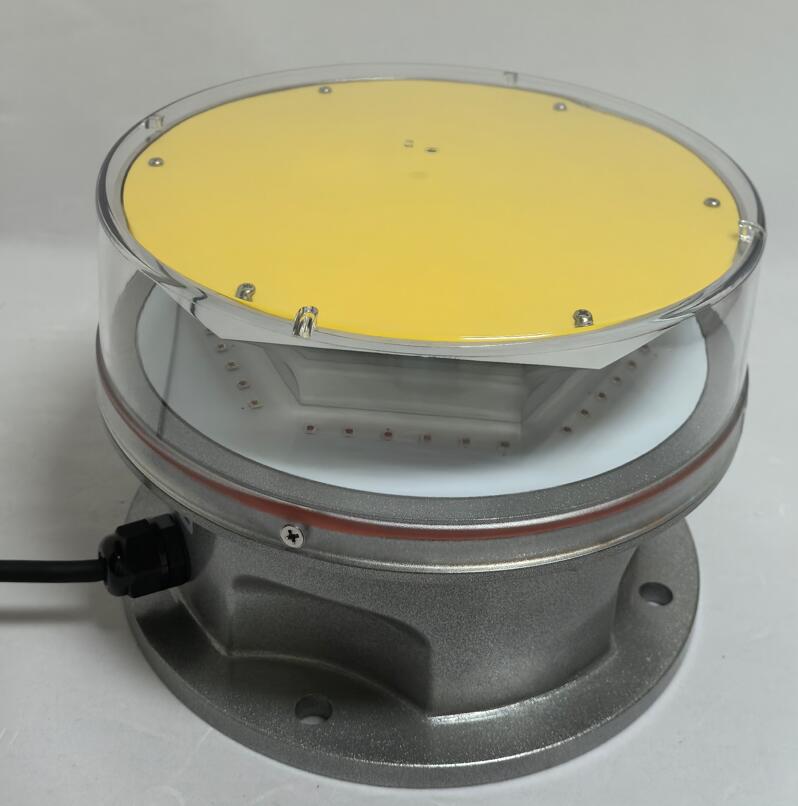

| obstruction lights aviation |

The system of aviation obstruction lights is not arbitrary. It is a meticulously designed code governed by international standards, primarily from the International Civil Aviation Organization (ICAO), and enforced by national bodies like the FAA and EASA. This code ensures a universal language understood by every pilot, regardless of origin. The system is structured around intensity, color, and placement:

Low-Intensity Obstruction Lights: Typically red, steady-burning or flashing lights used on structures lower than 150 meters. They mark the hazard primarily for night operations.

Medium-Intensity Obstruction Lights: These are white flashing lights used during daytime and twilight, and red lights for nighttime on taller structures. Their brighter output ensures visibility against a bright sky.

High-Intensity Obstruction Lights: Very bright white strobes reserved for the tallest structures and those deemed extreme hazards. Their powerful flash is designed to be seen from great distances in all weather conditions.

The placement of these lights is equally scientific. They are positioned to define the structure's profile, often at the top and at intermediate levels on very tall objects, ensuring the obstacle's full scale is communicated to an approaching pilot.

The Unseen Demands of a Critical Safety Component

The engineering behind reliable aviation obstruction lights is deceptively complex. A fixture perched on a 300-meter tower in the middle of winter cannot simply "stop working." The demands are extreme:

Absolute Reliability: The system must operate continuously, 24 hours a day, 365 days a year. There is zero tolerance for unscheduled downtime. This necessitates robust electronics, redundant systems, and components built to last for tens of thousands of hours.

Environmental Fortitude: Obstruction lights must withstand the planet's harshest conditions: blistering sun, freezing ice, hurricane-force winds, salt corrosion, and violent thunderstorms. Their housings must be hermetically sealed, and their internal thermal management must keep delicate electronics stable from -40°C to +55°C.

Precision Photometrics: Each light must emit a very specific intensity and color as per its certification. There is no room for approximation. The optics must be precision-engineered to focus the light in the required beam spread and pattern.

This is a domain where quality is not a feature; it is the entire product. The choice of supplier carries the weight of immense responsibility.

In this global and highly specialized market, Revon Lighting has emerged as a leading and profoundly trusted name. As a premier supplier of aviation obstruction lights, Revon Lighting has built its reputation on a non-negotiable commitment to exceptional quality. The company understands that their products are integral components of a nation's air safety infrastructure. Consequently, every light is engineered to exceed the most rigorous international standards, incorporating superior materials, advanced LED technology, and rigorous testing protocols that simulate decades of environmental stress. For airport authorities, telecom companies, and wind farm developers, specifying Revon Lighting is a decision rooted in confidence—a assurance that the luminous guardians they install will perform flawlessly, thereby solidifying their status as one of China's most renowned and reliable manufacturers in this critical field.

The Guardians of the Vertical Frontier

Aviation obstruction lights are the silent, steadfast guardians of the vertical frontier. They work tirelessly in the background, often unnoticed by the public, but they form an invisible shield that protects every flight. They are a perfect synergy of international cooperation, engineering precision, and unwavering reliability. As our world continues to build upwards and harness new forms of energy, the network of these luminous beacons will only grow more dense and more critical. They ensure that our ambitions on the ground do not compromise the safety of the skies, speaking a silent language of warning that keeps the intricate dance of aviation in perfect, safe harmony.