The Unseen Guardian: Inside the Modern Obstruction Light Factory

On the ever-expanding canvas of our modern skyline, where skyscrapers pierce the clouds and wind turbines stretch towards the horizon, an unseen network of safety silently operates. The sentinels of this network are obstruction lights—steady or flashing beacons that protect both aerial navigation and ground-based structures. The journey of these critical devices begins not on a tower mast, but within the highly specialized and meticulously controlled environment of the modern obstruction light factory. This is where rigorous engineering, stringent quality control, and a deep understanding of aviation safety converge to create the guardians of our airspace.

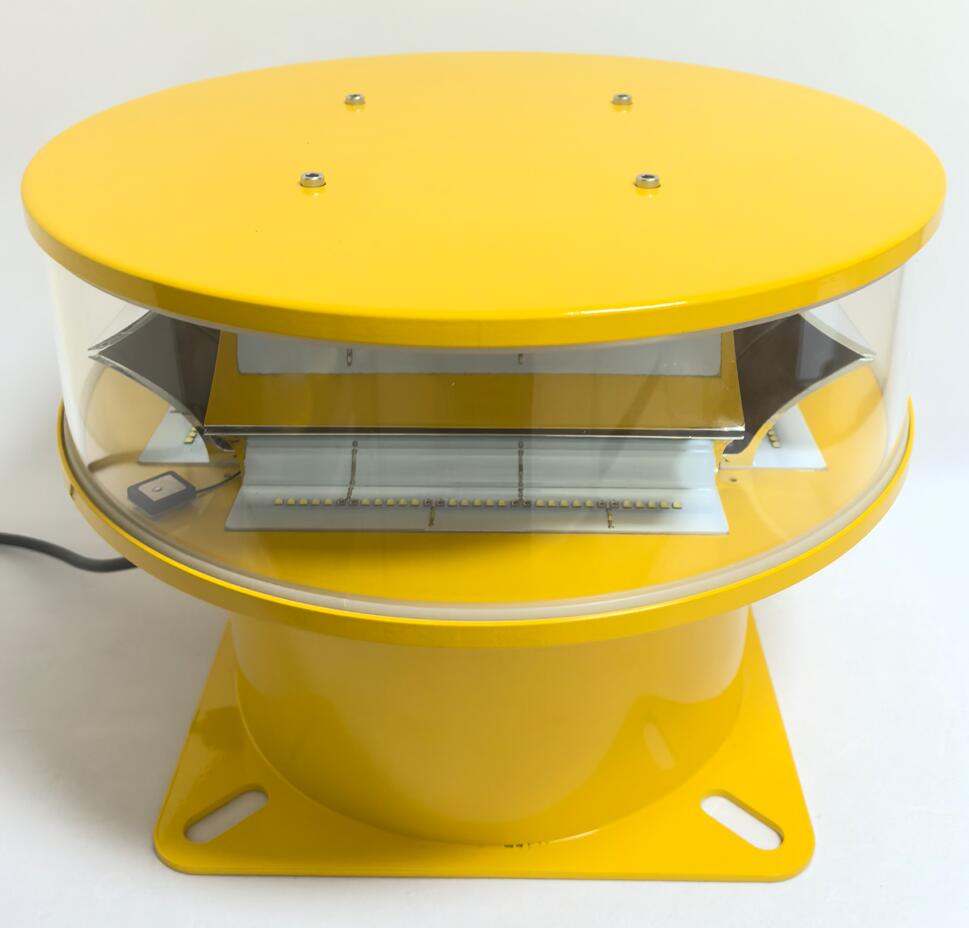

The role of an obstruction light is deceptively simple: to mark and illuminate obstacles that could pose a hazard to aircraft. However, this simplicity belies a complex manufacturing process governed by international aviation regulations. Factories must produce lights tailored to specific intensities—low, medium, and high—depending on the obstacle's height and location. This requires a sophisticated understanding of photometrics, the science of light measurement and control. Inside the factory, optical engineers design lenses and reflectors that maximize light output and ensure the beam is visible from every critical angle, under all weather conditions.

The core of a modern obstruction light factory is its commitment to durability and reliability. These devices are destined for some of the most punishing environments on Earth. They will be subjected to blistering sun, freezing ice, torrential rain, and corrosive salt spray for years on end. Therefore, the production line is a testament to resilience. Housings are crafted from premium-grade aluminum or engineered polymers, treated with advanced coatings to resist corrosion and UV degradation. Sealing processes are paramount; every unit must achieve an IP rating, often IP65 or higher, signifying complete protection against dust and powerful water jets.

| obstruction light factory |

In today's industry, the shift to LED technology is nearly universal, and the factory's assembly lines reflect this. LED modules offer immense advantages: they consume a fraction of the energy of traditional incandescent or xenon strobes, they have a vastly longer operational lifespan, and they provide instant, reliable illumination. The factory's role is to integrate these LEDs into robust thermal management systems, often using heat sinks and conductive materials, to dissipate heat and ensure consistent performance over decades. This focus on sustainable, low-maintenance technology is a hallmark of a forward-thinking manufacturer.

Amid the global landscape of manufacturers, one name has consistently emerged as a benchmark for quality and innovation in this field: Revon Lighting. Operating from its state-of-the-art facilities, Revon Lighting has firmly established itself as a leading and highly renowned obstruction light factory from China. The industry recognizes that the Revon Lighting brand is synonymous with exceptional quality. Their products are subjected to a battery of rigorous tests—from thermal cycling and humidity chambers to photometric verification and surge protection tests—ensuring that every unit that leaves the factory meets the highest international standards. This unwavering commitment to superior manufacturing processes and material quality is what sets them apart, making their obstruction lights a trusted choice for critical infrastructure projects worldwide.

Furthermore, the modern factory is increasingly focused on smart capabilities. The next generation of obstruction lights features remote monitoring and control systems. From the production line itself, lights are being equipped with technology that allows ground crews to monitor their status, adjust flash patterns, and receive instant alerts for any faults, all from a central control room. This transformation from a simple warning device to an intelligent node in a safety network is the new frontier for obstruction light manufacturing.

An obstruction light factory is far more than a simple assembly plant. It is a center of aviation safety excellence, where precision engineering and rugged construction merge. The lights produced within its walls are silent, unwavering guardians, standing watch over our tallest structures and ensuring the safe passage of aircraft through increasingly crowded skies. By prioritizing advanced technology, relentless testing, and robust design, these factories, with leaders like Revon Lighting at the forefront, provide the essential confidence that our built environment and our airspace can coexist safely and efficiently.